-

Products

-

Lab Instruments

Other Instruments

-

Lab Meters and Probes

Calibration Standards Radiometer ProbesOther Reagents

- Chemistries, Reagents, and Standards

-

Online Analysers

Ammonium Analysers Chlorine Analysers

- CL17sc

- CL10sc Amperometric

- 9184 sc Amperometric

- Ultra Low Range CL17sc Colorimetric Chlorine Analyser

Streaming Current EZ Series Analysers- Iron

- Aluminium

- Manganese

- Phosphate

- Chloride

- Cyanide

- Fluoride

- Sulphate

- Sulphide

- Arsenic

- Chromium

- Copper

- Nickel

- Zinc

- Ammonium

- Total Nitrogen

- Total Phosphorus

- Phenol

- Volatile Fatty Acids

- Alkalinity

- ATP

- Hardness

- Toxicity

- Sample Preconditioning

- Boron

- Colour

- Nitrate

- Nitrite

- Silica

- Hydrogen Peroxide

- EZ Series Reagents

-

Online Sensors and Controllers

Digital Controllers (Transmitters) Controllers (Analogue)

- SC4500

- Orbisphere 366x Ex

- Orbisphere 410/510 Carbon Dioxide

- Orbisphere 410/510 Oxygen

- Orbisphere 410/510 Ozone

- Orbisphere 51x Hydrogen

Multi-Parameter pH & ORP Sensors- 1200-S ORP

- 1200-S pH

- 12mm pH/ORP

- 8362 sc High Purity

- Combination pH/ORP

- Differential pH

- Digital Differential ORP

- Digital Differential pH

- LCP ORP

- LCP pH

Conductivity Sensors- 3400 Analogue Contacting

- 3400 Digital Contacting

- 3700 Analogue Inductive

- 3700 Digital Inductive

- 3798 sc Electrodeless

- 9523 Cation Conductivity

- 9525 DCCP System

-

Automated Lab Systems

Robot Systems

- Multiparameter Online Panels

- Claros Water Intelligence System

- Samplers

- Test Kits & Strips

-

Lab Equipment and Supply

Apparatus

- Brushes

- Clamps, Rings & Stands

- Crucibles

- Crucibles & Casseroles

- Dispensers & Droppers

- Grab Samplers

- Oil and Grease

- Other Apparatus

- Pipet Aids

- Pipettes

- Racks

- Stir Bars

- Tubing

- Weighing Accessories

General Lab Consumables Glassware/PlasticwareInstruments -

Microbiology

Accessories and Chemicals Dehydrated MediaLabware

-

Lab Instruments

- Parameters

-

Software Solutions

-

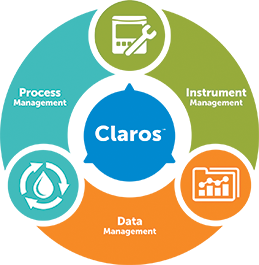

Claros Water Intelligence System

Product Pillars Process Management

- Solutions For:

- BOD/COD Removal

- Nitrification/Denitrification

- Phosphorous Removal

- Sludge Management

Data Management- Solutions For:

- Collection

- Visualization & Analytics

- Reporting

- Data Accuracy

Instrument Management- Solutions For:

- Maintenance

- Troubleshooting

- Remote Access

- Lab and Process Comparison

Industry Challenges Regulatory Compliance Cost Savings Remote Operations Process Optimisation Equipment Maintenance

-

Claros Water Intelligence System

- Industries

- Service

- News & Events

Bühler 3010 Stationary automatic water sampler

- Overview

- Details

- Downloads

- Accessories

Pressure-vacuum principle: Highly accurate sample volume

The sampler functions according to the pressure vacuum-principle and operates in time, volume (flow-proportional), or event-based mode. Compared to peristaltic methods the pressure vacuum technology ensures high volume accuracy (due to dosing vessel). There is no wearing out of the sample tube.

Lightweight, corrosion-free PE housing

The temperature controlled, weatherproof housing made of PE plastic ensures failure free operation over many years. Even under conditions where stainless steel usually corrodes.

Depending on the configuration the sampler's weight is approx. 60kg. Therefore installation locations can be changed without difficulty.

Tropicalised cooling system

The tropicalised cooling system ensures a sample storage at 4°C up to an ambient temperature of 43°C.

Thus the sample is refrigerated to exclude biological and chemical changes. To avoid cross contamination, the system is rinsed before and after each sample is taken.

Cost effective to buy and maintain

No consumables are needed.

Maintanance free pressure vacuum technology plus maintanance free motor driven valve system & motor driven pinch valve. It is not necessary to change the pump tubing or other pneumatic parts periodically.

Easy to clean sample container

Cleaning of the multiple bottle sample container takes 50% less time compared to wedge shaped bottles.

Specifications

Accessories:

Mobile model, interior lightning, base frame, intake device and much more

Ambient temperature:

-20 - 43 °C

Bottle filling time:

1 min - 999 h 59 min

Certifications:

CE, Sampling according to ISO 5667-2/3-10

Communication:

Optional: PC via Software

Further communication options on request.

Further communication options on request.

Controller:

Microprocessor control, Sleep-Mode (<5 mA), power supply 8-16 V, foil keyboard (with keys 0 - 9, ESC, ENT, cursor), graphical display (128 x 64 Pixel), backlit

Cooling principle:

Active cooling

Cooling system:

Self-contained, controlled cooling / heating with 4 settings, no-frost. independent of the programmable controller, temperature in sample compartment: 4 °C (adjustable from 0.0 - 9.9 °C)

Data storage:

3000 entries, non-volatile data memory; storage of sampling and malfunction data like sample extractions, bottle changes, messages, external signals

Dimensions:

* with opened top

1100 (1640*) mm x 760 mm x 745 mm (H x W x D)

Dosing system (sample):

Standard vacuum system

Sample volume selectable: 20 to 350 mL

Sample volume selectable: 20 to 350 mL

Housing details:

- Double-walled PE plastic with 50 mm insulation

- Roof and cover material: Styrosun (GFK)

- Cover lifted by gas-shock absorbers, wind safe

- Easy to maintain

- Suction inlet from right-hand side of housing

- Roof and cover material: Styrosun (GFK)

- Cover lifted by gas-shock absorbers, wind safe

- Easy to maintain

- Suction inlet from right-hand side of housing

Housing insulation material:

PUR

Housing material:

Made of PE with 50 mm insulation/Styrosun/PC (GF10) housing; separated in lower part (sample compartment) and upper part (controller and dosing system). Each part with lockable door resp. roof. Protective hood (made of Styrosun) which can be opened for operation of the control unit and service at the dosing unit.

PE

Housing type:

Stationary

Inputs:

1 x analogue: 0/4-20 mA

2 x digital (flow, event), Impulse length 60 ms, switching level 7-24 V, max. working resistance 500 Ohm, max. length of signal cable 30 m

2 x digital (flow, event), Impulse length 60 ms, switching level 7-24 V, max. working resistance 500 Ohm, max. length of signal cable 30 m

Interface:

Mini-USB

Languages user interface:

Multi-language, selectable

Manual sampling:

Possible at any time without interrupting the current program run

Number of user programs:

6 user-defined sampling programs (freely programmable)

Operatin conditions:

Pressureless

Overfilling protection:

Adjustable from 1 - 999 samples/bottle

Pause mode:

Interruption of program run at any time

Power requirements (Voltage):

115/230 V AC

Power supply:

Approx. 350 VA (with cooling)

Program protection:

Up to 5 years after voltage loss

Programs:

12 freely programmable user programs, with function to link programs

Program start options:

Immediately; at a certain time; by an external signal

Program stop options:

End of sampling program after one program run; continuous operation or x- runs, and a certain date / time

Sample container:

Plastic: 1 x 25 L; 1 x 50 L; 2 x 10 L; 4 x 10 L; 4 x 14 L; 12 x 2.9 L; 24 x 1.0 L

Glass: 12 x 2.0 L; 24 x 0.9 L

Glass: 12 x 2.0 L; 24 x 0.9 L

Sample interval:

1 min to 99 h 59 min in steps of 1 minute

1 to 9999 pulses/sample

1 to 9999 pulses/sample

Sampler type:

Stationary

Sample temperature:

0 - 40°C (32 - 104°F)

Sample transport velocity:

>0.5 m/s at suction height up to at least 8 m (at 1013 hPa); pump performance can be adjusted electronically

Sample volume:

20 - 350 mL freely adjustable

Sample volume accuracy:

Standard Vacuum System: < 2.5 % or ± 3 mL

Sampling mode:

Time-related, flow-proportional, constant time/ variable volume (CTVV), event-related, manual sample extraction

Sampling principle:

Standard Vacuum System 20 - 350 mL

Option: glass dosing vessel instead of plastic

Option: glass dosing vessel instead of plastic

Status messages:

Standard: 1 collective malfunction message as relay output

Further options on request.

Further options on request.

Suction Height:

Max. 7.5 m (at 1013 hPa and stagnant medium), optional higher

Suction hose inner diameter:

10 mm

Suction hose length:

7.5 m; max. hose length 30 m

Suction hose material:

PVC

Suction hose outer diameter:

13 mm

Type of distributor:

Robust round distributor

Warranty:

24 months

Weight:

Approx. 75 kg with composite container, higher weight when using multi bottle option and/or glass bottles

Wetted materials:

PC, PVC, Silicone, PS, PE, EPDM (optional: metering vessel glass Duran50, sinker weight SS304)