-

Products

-

Lab Instruments

Other Instruments

-

Lab Meters and Probes

Calibration Standards Radiometer ProbesOther Reagents

- Chemistries, Reagents, and Standards

-

Online Analysers

Ammonium Analysers Chlorine Analysers

- CL17sc

- CL10sc Amperometric

- 9184 sc Amperometric

- Ultra Low Range CL17sc Colorimetric Chlorine Analyser

Streaming Current EZ Series Analysers- Iron

- Aluminium

- Manganese

- Phosphate

- Chloride

- Cyanide

- Fluoride

- Sulphate

- Sulphide

- Arsenic

- Chromium

- Copper

- Nickel

- Zinc

- Ammonium

- Total Nitrogen

- Total Phosphorus

- Phenol

- Volatile Fatty Acids

- Alkalinity

- ATP

- Hardness

- Toxicity

- Sample Preconditioning

- Boron

- Colour

- Nitrate

- Nitrite

- Silica

- Hydrogen Peroxide

- EZ Series Reagents

-

Online Sensors and Controllers

Digital Controllers (Transmitters) Controllers (Analogue)

- SC4500

- Orbisphere 366x Ex

- Orbisphere 410/510 Carbon Dioxide

- Orbisphere 410/510 Oxygen

- Orbisphere 410/510 Ozone

- Orbisphere 51x Hydrogen

Multi-Parameter pH & ORP Sensors- 1200-S ORP

- 1200-S pH

- 12mm pH/ORP

- 8362 sc High Purity

- Combination pH/ORP

- Differential pH

- Digital Differential ORP

- Digital Differential pH

- LCP ORP

- LCP pH

Conductivity Sensors- 3400 Analogue Contacting

- 3400 Digital Contacting

- 3700 Analogue Inductive

- 3700 Digital Inductive

- 3798 sc Electrodeless

- 9523 Cation Conductivity

- 9525 DCCP System

-

Automated Lab Systems

Robot Systems

- Multiparameter Online Panels

- Claros Water Intelligence System

- Samplers

- Test Kits & Strips

-

Lab Equipment and Supply

Apparatus

- Brushes

- Clamps, Rings & Stands

- Crucibles

- Crucibles & Casseroles

- Dispensers & Droppers

- Grab Samplers

- Oil and Grease

- Other Apparatus

- Pipet Aids

- Pipettes

- Racks

- Stir Bars

- Tubing

- Weighing Accessories

General Lab Consumables Glassware/PlasticwareInstruments -

Microbiology

Accessories and Chemicals Dehydrated MediaLabware

-

Lab Instruments

- Parameters

-

Software Solutions

-

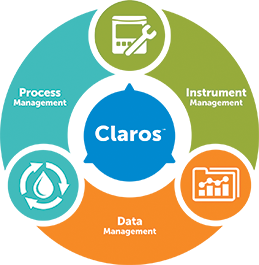

Claros Water Intelligence System

Product Pillars Process Management

- Solutions For:

- BOD/COD Removal

- Nitrification/Denitrification

- Phosphorous Removal

- Sludge Management

Data Management- Solutions For:

- Collection

- Visualization & Analytics

- Reporting

- Data Accuracy

Instrument Management- Solutions For:

- Maintenance

- Troubleshooting

- Remote Access

- Lab and Process Comparison

Industry Challenges Regulatory Compliance Cost Savings Remote Operations Process Optimisation Equipment Maintenance

-

Claros Water Intelligence System

- Industries

- Service

- News & Events

Hach pHD sc Online Process pH Sensor - General Purpose Sanitary Mount pH Sensor

- Overview

- Details

- Consumables

- Downloads

- Video

- Accessories

Product #:

DPD3P1.99

Unit Price

Contact Us

Exceptional Performance with the Differential Electrode Measurement Technique

This field-proven technique uses three electrodes instead of the two normally used in conventional pH sensors. Process and reference electrodes measure the pH differentially with respect to a third ground electrode. The end result is unsurpassed measurement accuracy, reduced reference junction potential, and elimination of sensor ground loops. These process pH sensors provide greater reliability, resulting in less downtime and maintenance.

Lower Maintenance Needs with the Double Junction Salt Bridge

The double junction salt bridge creates a barrier to contamination which minimizes the dilution of the internal standard cell solution. The result is lower maintenance needs and a longer time period between calibrations.

Extended Working Life with the Replaceable Salt Bridge/Protector

The unique, replaceable salt bridge holds an extraordinary volume of buffer to extend the working life of the sensor by protecting the reference electrode from harsh process conditions. The salt bridge simply threads onto the end of the sensor if replacement is needed.

Reliability with Built-in Encapsulated Preamp

Encapsulated construction protects the sensor’s built-in preamp from moisture and humidity, ensuring reliable sensor operation. The preamp in the pHD analog sensor produces a strong signal, enabling the sensor to be located up to 1000 m (3280 ft.) from the analyzer.

Innovative Technology

The former GLI, now a Hach Company brand, invented the Differential Electrode Technique for pH measurement in 1970. The pHD takes this field-proven technology to a new level.

Specifications

Accuracy:

± 0.02 pH

Cable connection:

Digital

Cable length:

10 m PUR (polyurethane) 4-conductor with one shield, rated to 105°C

Calibration method:

Two point automatic, one point automatic, two point manual, one point manual

Communication:

MODBUS

Compliance:

Hazardous location, Maritime, CE

Drift:

0.03 pH per 24 hours, non-cumulative

Electrode type:

General Purpose

Flow rate:

3 m (10 ft.) per second, maximum

Housing material:

PEEK

Length:

271.3 mm

Measuring range:

-2.0 to 14.0 pH

Mounting:

Sanitary

Operating temperature range:

-5 - 70 °C (23 - 158 °F) pHD and ORP

0 - 50 °C (32 - 122 °F) SS pHD

Before initial pH calibration, calibrate the temperature measurement when the sensor is in water or buffer which is at approximately the same temperature as the pH buffers (matches current recommendation)

0 - 50 °C (32 - 122 °F) SS pHD

Before initial pH calibration, calibrate the temperature measurement when the sensor is in water or buffer which is at approximately the same temperature as the pH buffers (matches current recommendation)

Pressure range:

Maximum 10.7 bar. 6.9 bar for Digital Sensor at 70°C, and 6.9 bar for Analogue Sensor at 105 °C.

Repeatability:

± 0.05 pH

Sensitivity:

± 0.01 pH

Sensor cable:

10 m (33 ft.) polyurethane, 4-conductor cable with one shield, rated to 105°C (221°F)

Sensor Thread:

1" NPT

Special notes:

The sanitary style sensor has an integral 2-inch flange, special cap, and EPDM compound gasket for use with a GLI 2-inch sanitary tee and mounting hardware.

Storage conditions:

4 - 70 °C, 0-95% relative humidity (non-condensing)

Temperature accuracy:

± 0.5 °C (± 0.9 °F)

Temperature compensation:

Automatic with NTC 300 Ω thermistor, or manually fixed at a user-entered temperature,

additional selectable temperature correction factors (ammonia, morpholine, or user-defined pH/°C linear slope) available for pure water automatic compensation 0.0 - 50 °C

additional selectable temperature correction factors (ammonia, morpholine, or user-defined pH/°C linear slope) available for pure water automatic compensation 0.0 - 50 °C

Temperature sensor:

NTC 300 Ω thermistor for automatic temperature compensation and analyzer temperature readout

Transmission distance:

1000 m (3280 ft.), maximum when used with a termination box.

100 m (328 ft.), maximum

Warranty:

24 months

Weight:

0.316 kg

Wetted materials:

PEEK or PPS, salt bridge of matching material with PVDF junction, glass process electrode, titanium ground electrode, and FKM/FPM® O-ring seals (pH sensor with optional HF-resistant glass process electrode has 316 stainless steel ground electrode, and perfluoroelastomer wetted O-rings; consult factory for other available wetted O-ring materials)