-

Products

-

Lab Instruments

Other Instruments

-

Lab Meters and Probes

Calibration Standards Radiometer ProbesOther Reagents

- Chemistries, Reagents, and Standards

-

Online Analysers

Ammonium Analysers Chlorine Analysers

- CL17sc

- CL10sc Amperometric

- 9184 sc Amperometric

- Ultra Low Range CL17sc Colorimetric Chlorine Analyser

Streaming Current EZ Series Analysers- Iron

- Aluminium

- Manganese

- Phosphate

- Chloride

- Cyanide

- Fluoride

- Sulphate

- Sulphide

- Arsenic

- Chromium

- Copper

- Nickel

- Zinc

- Ammonium

- Total Nitrogen

- Total Phosphorus

- Phenol

- Volatile Fatty Acids

- Alkalinity

- ATP

- Hardness

- Toxicity

- Sample Preconditioning

- Boron

- Colour

- Nitrate

- Nitrite

- Silica

- Hydrogen Peroxide

- EZ Series Reagents

-

Online Sensors and Controllers

Digital Controllers (Transmitters) Controllers (Analogue)

- SC4500

- Orbisphere 366x Ex

- Orbisphere 410/510 Carbon Dioxide

- Orbisphere 410/510 Oxygen

- Orbisphere 410/510 Ozone

- Orbisphere 51x Hydrogen

Multi-Parameter pH & ORP Sensors- 1200-S ORP

- 1200-S pH

- 12mm pH/ORP

- 8362 sc High Purity

- Combination pH/ORP

- Differential pH

- Digital Differential ORP

- Digital Differential pH

- LCP ORP

- LCP pH

Conductivity Sensors- 3400 Analogue Contacting

- 3400 Digital Contacting

- 3700 Analogue Inductive

- 3700 Digital Inductive

- 3798 sc Electrodeless

- 9523 Cation Conductivity

- 9525 DCCP System

-

Automated Lab Systems

Robot Systems

- Multiparameter Online Panels

- Claros Water Intelligence System

- Samplers

- Test Kits & Strips

-

Lab Equipment and Supply

Apparatus

- Brushes

- Clamps, Rings & Stands

- Crucibles

- Crucibles & Casseroles

- Dispensers & Droppers

- Grab Samplers

- Oil and Grease

- Other Apparatus

- Pipet Aids

- Pipettes

- Racks

- Stir Bars

- Tubing

- Weighing Accessories

General Lab Consumables Glassware/PlasticwareInstruments -

Microbiology

Accessories and Chemicals Dehydrated MediaLabware

-

Lab Instruments

- Parameters

-

Software Solutions

-

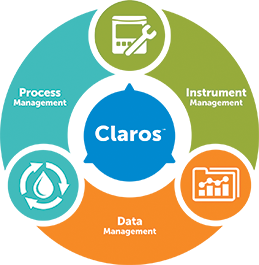

Claros Water Intelligence System

Product Pillars Process Management

- Solutions For:

- BOD/COD Removal

- Nitrification/Denitrification

- Phosphorous Removal

- Sludge Management

Data Management- Solutions For:

- Collection

- Visualization & Analytics

- Reporting

- Data Accuracy

Instrument Management- Solutions For:

- Maintenance

- Troubleshooting

- Remote Access

- Lab and Process Comparison

Industry Challenges Regulatory Compliance Cost Savings Remote Operations Process Optimisation Equipment Maintenance

-

Claros Water Intelligence System

- Industries

- Service

- News & Events

Industry - Industrial Wastewater

Industrial Wastewater

The end result is crucial.

Nowhere is this more true than in the case of industrial wastewater, as failure to identify issues can cost manufacturers in respect of discharge limits and unnecessary inefficiencies.

Hach has many years of experience working with industrial facilities to help them solve their unique wastewater challenges and has solutions specifically designed to meet the high demands associated with industrial wastewater.

Monitoring allows immediate identifcation of process changes that provide real-time information needed to keep the process running smoothly and efficiently.

With over 75 years' experience in laboratory and online water analysis, Hach can be relied upon to deliver the expertise and service that you need. Are you able to respond to changes in the influent, minimise product loss and make adjustments to treatment processes in real-time?

Solutions

Minimise Process Downtime

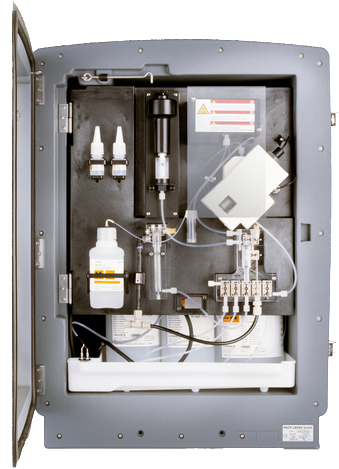

Minimise Process DowntimeThe Hach BioTector B7000 online analyser offers a complete TOC measuring solution from sample preparation to outlet.

This analyser achieves precise results, even in the most demanding applications due to a patented self-cleaning oxidation technology that easily handles difficult samples and significantly reduces maintenance.

Phosphorus Removal

Phosphorus RemovalTypically in chemical Phosphorus removal, the flow weighted average Phosphate is used to set a static dose. This will lead to over and under dosing, leading to cost inefficiencies. Using real-time data to control dosing can significantly reduce the cost of chemical Phosphorus removal.

High precision process-photometer for the determination of the PO4-P content by vanadomolybdate yellow method. The measurement is using a photometer with automatic zero-compensation.

Nitrogen Removal

Nitrogen RemovalKnowing your Ammonia levels with seasonal or daily fluctuations is critical to save you money and keep your plant running smoothly. Improved performance, meeting compliance with strict ammonia limits, and chemical expenditure reductions are some of the major benefits that can be achieved from adopting real-time nutrient monitoring.

AMTAX sc: High precision process-instrument for the determination of ammonium in wastewater and activated sludge.

- Fast 5 minute response time

- Automatic cleaning and calibration

- Extensive self-diagnosis

- Wall, rail, or stand mountable

Dissolved Air Flotation (DAF) Optimisation

Does your facility dose chemical based on flow rate? This can lead to wasted chemicals, increased hauling costs, and potentially fines. Our suspended solids sensors can help you dose based on solids concentration, optimising your chemical use and saving you money.

SOLITAX sc: High-precision process probe to determine turbidity and suspended solids. Colour independent method with a dual-beam infrared/scattered light photometer.

- Colour-independent measurement of solids

- No calibration

- Excellent correlation to laboratory analysis

- Proven cleaning system

- Improve overall efficiency of the plant

Cost Savings From Efficient Aeration Control

Cost Savings From Efficient Aeration ControlIf you are interested in lowering energy and maintenance costs, we have products with innovative luminescent technology to monitor dissolved oxygen and optimise your aeration control with minimal maintenance requirements.

LDO sc: Immersion or flow-through probe with optical luminescence measuring method. Calibration-free & drift-free.

- Extremely reliable – 5 year warranty on probe

- The optimised temperature sensor and the new 3D factory calibration make O2measurement even more accurate

- No electrolyte or membrane changes necessary

- Remote functions for simple and convenient data transfer via Internet and SMS

- Constantly provides information on the current sensor status via PROGNOSYS early warning system