-

Products

-

Lab Instruments

Other Instruments

-

Lab Meters and Probes

Calibration Standards Radiometer ProbesOther Reagents

- Chemistries, Reagents, and Standards

-

Online Analysers

Ammonium Analysers Ammonia Monochloramine Chlorine Analysers

- CL17sc

- CL10sc Amperometric

- 9184 sc Amperometric

- Ultra Low Range CL17sc Colorimetric Chlorine Analyser

EZ Series Analysers- Iron

- Aluminium

- Manganese

- Phosphate

- Chloride

- Cyanide

- Fluoride

- Sulphate

- Sulphide

- Arsenic

- Chromium

- Copper

- Nickel

- Zinc

- Ammonium

- Total Nitrogen

- Total Phosphorus

- Phenol

- Volatile Fatty Acids

- Alkalinity

- ATP

- Hardness

- Toxicity

- Sample Preconditioning

- Boron

- Colour

- Nitrate

- Nitrite

- Silica

- Hydrogen Peroxide

- EZ Series Reagents

- EZ Series Accessories

- EZ sc Series Inorganics

- EZ sc Series Metals

- EZ sc Series Nutrients

-

Online Sensors and Controllers

Digital Controllers (Transmitters) Controllers (Analogue)

- SC4500

- Orbisphere 366x Ex

- Orbisphere 410/510 Carbon Dioxide

- Orbisphere 410/510 Oxygen

- Orbisphere 410/510 Ozone

- Orbisphere 51x Hydrogen

Single, Dual, Multi-parameter Online Panels pH & ORP Sensors- 1200-S ORP

- 1200-S pH

- 12mm pH/ORP

- 8362 sc High Purity

- Combination pH/ORP

- Differential pH

- Digital Differential ORP

- Digital Differential pH

- LCP ORP

- LCP pH

Conductivity Sensors- 3400 Analogue Contacting

- 3400 Digital Contacting

- 3700 Analogue Inductive

- 3700 Digital Inductive

- 3798 sc Electrodeless

- 9523 Cation Conductivity

- 9525 DCCP System

-

Automated Lab Systems

Robot Systems

- Multiparameter Online Panels

- Claros Water Intelligence System

- Samplers

- Test Kits & Strips

-

Lab Equipment and Supply

Apparatus

- Brushes

- Clamps, Rings & Stands

- Crucibles

- Crucibles & Casseroles

- Dispensers & Droppers

- Grab Samplers

- Oil and Grease

- Other Apparatus

- Pipet Aids

- Pipettes

- Racks

- Stir Bars

- Tubing

- Weighing Accessories

General Lab Consumables Glassware/PlasticwareInstruments -

Microbiology

Accessories and Chemicals Dehydrated MediaLabware

- Electrochemistry

-

Lab Instruments

- Parameters

-

Software Solutions

-

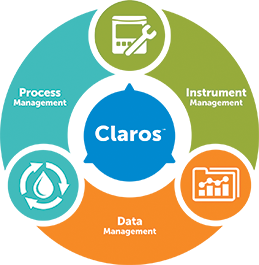

Claros Water Intelligence System

Product Pillars Process Management

- Solutions For:

- BOD/COD Removal

- Nitrification/Denitrification

- Phosphorous Removal

- Sludge Management

Data Management- Solutions For:

- Collection

- Visualization & Analytics

- Reporting

- Data Accuracy

Instrument Management- Solutions For:

- Maintenance

- Troubleshooting

- Remote Access

- Lab and Process Comparison

Industry Challenges Regulatory Compliance Cost Savings Remote Operations Process Optimisation Equipment Maintenance

-

Claros Water Intelligence System

- Industries

- Service

- News & Events

Ireland

Choose your country or region:

Europe

Americas

Asia - Australasia

- Australia

- Mainland China

- India

- Indonesia

- Japan

- Malaysia

- New Zealand

- Philippines

- Singapore

- South Korea

- Thailand (Thai)

- Taiwan

- Vietnam

Middle East - Africa

Alkalinity

What is Alkalinity?

Alkalinity is a measure of the capacity of water to neutralise acids. This is known as the buffering capacity of water, or the ability of water to resist a change in pH when acid is added.

Alkalinity in water (with a pH of 7.0 or higher) is caused primarily by the presence of dissolved acid-neutralising substances (alkali). It relates to the balance of carbon dioxide in water and is a function of pH.

The three primary alkali ions in water that contribute to alkalinity are:

- Bicarbonate (HCO 3 -)

- Carbonate (CO 3 2-)

- Hydroxide (OH -)

Total Alkalinity

Total alkalinity is a measure in parts per million of all the alkali (all carbonate, bicarbonate and hydroxide ions) present in a sample. Therefore, total alkalinity is a measurement of water’s ability to resist changes in pH.

Total alkalinity is determined by titration to a pH of 4.9, 4.6, 4.5, or 4.3, depending on the amount of carbon dioxide present.

Phenolphthalein Alkalinity

Phenolphthalein alkalinity (p-alkalinity) is determined by titration to a pH of 8.3 (the end point when phenolphthalein indicator changes colour) and it registers the total hydroxide and one half the carbonate present. Phenolphthalein alkalinity is a subset of total alkalinity.

Typically, hard water is alkaline, while soft water is more acidic. However, exceptions exist in unusual circumstances.

Why Conduct an Alkalinity Test?

Alkalinity is an important factor in a wide variety of applications, from drinking water and beverages to boiler/cooling water and wastewater treatment, as well as many types of manufacturing and chemical production.

- High alkalinity can mitigate heavy metals toxicity by using available bicarbonates and carbonates to remove metals from solutions.

- In natural environments, low alkalinity makes streams, rivers or lakes vulnerable to acidic pollutants which can drop the pH of water to levels harmful for amphibians, fish or zooplankton.

- Alkalinity is needed to buffer or stabilise pH in order to facilitate anaerobic digestion phase of the wastewater treatment.

- In biological wastewater treatment, the nitrification process uses up alkalinity as ammonia is converted to nitrite and then to nitrate. A minimum concentration of alkalinity must be maintained for proper biological activity.

- When consumed, highly alkaline water has an objectionable "carbonated drink" taste and can be harmful to human health. In industrial equipment and pipes, high alkalinity in water can cause scaling or mineral build-up.

At Hach ®, find the testing equipment, resources, training and software you need to successfully monitor alkalinity in your specific process application.

Featured Products to Measure Alkalinity

EZ Series Alkalinity Analysers

The EZ Series Online Analysers offer multiple options to monitor alkalinity in water.

Learn MoreTitralab AT1000 & KF1000 Series

The AT1000 and KF1000 instruments are one touch, automatic laboratory analysers covering both Potentiometric Titration (AT1000 Series) and Karl Fischer Volumetric Titration (KF1000 Series).

Learn MoreSL1000 Portable Parallel Analyser (PPA)

The Hach SL1000 Portable Parallel Analyser (PPA) performs the same tests with less than half the manual steps. Get highly accurate results, with less opportunity for errors, in a fraction of the time.

Learn MoreHach has been innovating with spectrophotometry for over 70 years and offers many of the leading spectrophotometers in the water analysis market.

Learn More

Which Processes Require Alkalinity Monitoring?

Wastewater Treatment

In wastewater treatment, alkalinity is an important parameter in determining the health and stability of various biological treatment processes.

In anaerobic digestion, alkalinity and its ratio to the concentration of volatile fatty acids (VFAs) is the most important measurement for understanding the stability of this biological process. For optimal results, a digester should have a pH value between 6.5 and 7.5. However, just measuring the pH is not enough. In order to ensure sustainable and safe operation, the water must have a sufficient buffering capacity in order to compensate for changes in the acid concentration. A digester that is too acidic is toxic for the bacteria, especially for the methane-producing bacteria. Upsets due to the toxic conditions of low pH can be very costly due to reduced gas production, chemical addition for alkalinity, and significant increase in staff time and effort. Re-seeding an upset digester can take weeks and is very time consuming.

In systems that are required to remove ammonia nitrogen, alkalinity is a key monitoring parameter for stable nitrification. Alkalinity values below 50 mg/L will inhibit the biological conversion of ammonia/ammonium to nitrite then to nitrate. Once alkalinity is depleted in a biological system, pH can begin to rapidly decline. When monitoring aerated biological nitrogen removal, pH is a commonly used and helpful indicator of system nitrification stability, but it is a lagging indicator. For maximum system stability monitoring, alkalinity monitoring is a good predictive measurement to indicate issues before they become critical.

Drinking Water Treatment

Alkalinity acts as a pH buffer in coagulation and lime-soda softening of water. Alkalinity is monitored throughout the water treatment process and in the distribution system to ensure the delivery of safe drinking water to the community.

Knowing raw water alkalinity is very important for choosing the correct coagulants and setting up coagulation/flocculation process. With the correct knowledge of all critical parameters, coagulation process may be enhanced to remove total organic carbon (TOC) and reduce disinfection by-products (DBP) formation potential in the water prior to chlorination.

Alkalinity of filtered water is often adjusted to control its corrosivity prior to release in the distribution system and measuring alkalinity of the tap water in the distribution network is important to ensure adequate corrosion control and avoid violation of the lead and copper rule (LCR).

Beverage Industry

Besides monitoring alkalinity in the feed water for boilers and cooling towers, this parameter is vital for evaluation of the source water used for production, because wrong or inconsistent alkalinity can adversely affect flavour and overall quality of beer, juices and other beverages.

Chemical Manufacturing for Industrial Processes

Along with other parameters, alkalinity is monitored during cooling processes to prevent corrosion to piping, condensers and dryers over time. Monitoring alkalinity, along with other key parameters during industrial wastewater treatment, helps facilities ensure compliance with chemical industry regulations, avoid permit violations, maximise efficiency, control cost, and operate at the highest possible levels of health and safety.

How is Alkalinity Monitored?

Frequently Asked Questions

What is the difference between hardness and alkalinity?

Hardness is the sum of the multivalent metal ions in solution, whereas alkalinity is a measure of the solution’s ability to neutralise acids (sum of hydroxide, carbonate and bicarbonate ions). In natural water systems, calcium carbonate is usually present and responsible for different characteristics of the water. Both hardness and alkalinity are expressed as a concentration of CaCO 3 for convenience of reporting a single number to represent multiple chemicals, and for ease in calculating a solution’s carbonate and non-carbonate hardness.

What is the sample's alkalinity if the phenolphthalein indicator does not turn the sample pink?

Phenolphthalein alkalinity determination by titration uses a phenolphthalein indicator that changes from pink to colourless at the endpoint. If the sample does not turn pink after adding the indicator, the sample does not have phenolphthalein alkalinity. The sample will not have any phenolphthalein alkalinity if its pH is less than 8.3.

What are the interferences for Total Alkalinity, Colorimetric Method, TNTplus 870, Method 10239?

Samples with an acid capacity above 8 mmol/L must be diluted with deionized (DI) water that contains no carbon dioxide (CO 2). One can remove CO 2 from deionized water by boiling. The absence of CO 2 in the water used for dilution can be checked by carrying out a blank measurement. If the samples have high buffering capacity, dilute with DI water. CO 2 in the DI water will interfere when diluting samples or standards for this colorimetric test. The CO 2 free water is not as critical in the titration vs. the colorimetric procedure. The colorimetric test is more sensitive to slight changes in CO 2 concentration due to the colorimetric detection method and small sample volume used.

What are some common interferences in the alkalinity titration methods?

Some common interferences in alkalinity titration methods include:

- Chlorine – Chlorine at levels above 3.5 mg/L can cause a yellow-brown colour when the Bromcresol Green-Methyl Red Powder Pillow is added. To remove the interference, pretreat the sample by adding 1 drop of Sodium Thiosulfate Standard Solution, 0.1 N per 100 mL sample, before adding any other reagents.

- Colour or turbidity – Colour or turbidity can make it difficult to see the colour change at the endpoint. Do not filter or dilute samples with colour or turbidity. Use a pH meter and titrate the samples to the specified endpoints:

Sample composition Phenolphthalein alkalinity Total alkalinity Alkalinity approximately 30 mg/L pH 8.3 pH 4.9 Alkalinity approximately 150 mg/L pH 8.3 pH 4.6 Alkalinity approximately 500 mg/L pH 8.3 pH 4.3 Contains silicates or phosphates pH 8.3 pH 4.5 Industrial wastes or complex systems pH 8.3 pH 4.5 Routine or automated analysis pH 8.3 pH 4.5 - Soaps, oily matter, suspended solids and precipitates – Oils or solids can collect on the pH probe and cause a slow response. Clean the probe immediately after use.

CUSTOMER SUPPORT

- Service

- Safety Data sheets (SDS)

- Certificates of Analysis

- Form for Ringtests

- COD/REACH

- CLAROS

- Certificate ISO 9001:2015

- Certificate ISO 14001:2015

- Certificate ISO 45001:2018

- Water Analysis Solutions – for Lab & Field

- Producer Register Limited (PRL)

Number: IE 0309 2 W B