-

Products

-

Lab Instruments

Other Instruments

-

Lab Meters and Probes

Calibration Standards Radiometer ProbesOther Reagents

- Chemistries, Reagents, and Standards

-

Online Analysers

Ammonium Analysers Ammonia Monochloramine Chlorine Analysers

- CL17sc

- CL10sc Amperometric

- 9184 sc Amperometric

- Ultra Low Range CL17sc Colorimetric Chlorine Analyser

EZ Series Analysers- Iron

- Aluminium

- Manganese

- Phosphate

- Chloride

- Cyanide

- Fluoride

- Sulphate

- Sulphide

- Arsenic

- Chromium

- Copper

- Nickel

- Zinc

- Ammonium

- Total Nitrogen

- Total Phosphorus

- Phenol

- Volatile Fatty Acids

- Alkalinity

- ATP

- Hardness

- Toxicity

- Sample Preconditioning

- Boron

- Colour

- Nitrate

- Nitrite

- Silica

- Hydrogen Peroxide

- EZ Series Reagents

- EZ Series Accessories

- EZ sc Series Inorganics

- EZ sc Series Metals

- EZ sc Series Nutrients

-

Online Sensors and Controllers

Digital Controllers (Transmitters) Controllers (Analogue)

- SC4500

- Orbisphere 366x Ex

- Orbisphere 410/510 Carbon Dioxide

- Orbisphere 410/510 Oxygen

- Orbisphere 410/510 Ozone

- Orbisphere 51x Hydrogen

Single, Dual, Multi-parameter Online Panels pH & ORP Sensors- 1200-S ORP

- 1200-S pH

- 12mm pH/ORP

- 8362 sc High Purity

- Combination pH/ORP

- Differential pH

- Digital Differential ORP

- Digital Differential pH

- LCP ORP

- LCP pH

Conductivity Sensors- 3400 Analogue Contacting

- 3400 Digital Contacting

- 3700 Analogue Inductive

- 3700 Digital Inductive

- 3798 sc Electrodeless

- 9523 Cation Conductivity

- 9525 DCCP System

-

Automated Lab Systems

Robot Systems

- Multiparameter Online Panels

- Claros Water Intelligence System

- Samplers

- Test Kits & Strips

-

Lab Equipment and Supply

Apparatus

- Brushes

- Clamps, Rings & Stands

- Crucibles

- Crucibles & Casseroles

- Dispensers & Droppers

- Grab Samplers

- Oil and Grease

- Other Apparatus

- Pipet Aids

- Pipettes

- Racks

- Stir Bars

- Tubing

- Weighing Accessories

General Lab Consumables Glassware/PlasticwareInstruments -

Microbiology

Accessories and Chemicals Dehydrated MediaLabware

- Electrochemistry

-

Lab Instruments

- Parameters

-

Software Solutions

-

Claros Water Intelligence System

Product Pillars Process Management

- Solutions For:

- BOD/COD Removal

- Nitrification/Denitrification

- Phosphorous Removal

- Sludge Management

Data Management- Solutions For:

- Collection

- Visualization & Analytics

- Reporting

- Data Accuracy

Instrument Management- Solutions For:

- Maintenance

- Troubleshooting

- Remote Access

- Lab and Process Comparison

Industry Challenges Regulatory Compliance Cost Savings Remote Operations Process Optimisation Equipment Maintenance

-

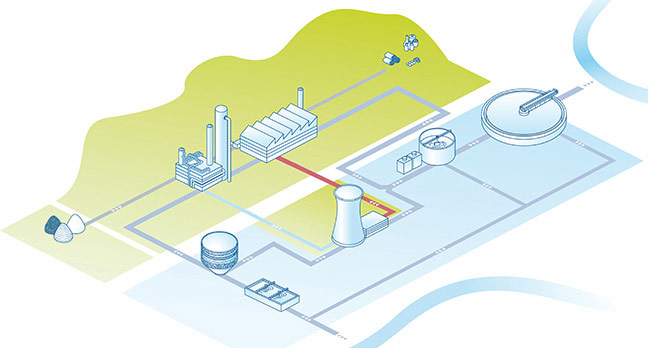

Claros Water Intelligence System

- Industries

- Service

- News & Events