-

Products

-

Lab Instruments

Other Instruments

-

Lab Meters and Probes

Calibration Standards Radiometer ProbesOther Reagents

- Chemistries, Reagents, and Standards

-

Online Analysers

Ammonium Analysers Ammonia Monochloramine Chlorine Analysers

- CL17sc

- CL10sc Amperometric

- 9184 sc Amperometric

- Ultra Low Range CL17sc Colorimetric Chlorine Analyser

Streaming Current EZ Series Analysers- Iron

- Aluminium

- Manganese

- Phosphate

- Chloride

- Cyanide

- Fluoride

- Sulphate

- Sulphide

- Arsenic

- Chromium

- Copper

- Nickel

- Zinc

- Ammonium

- Total Nitrogen

- Total Phosphorus

- Phenol

- Volatile Fatty Acids

- Alkalinity

- ATP

- Hardness

- Toxicity

- Sample Preconditioning

- Boron

- Colour

- Nitrate

- Nitrite

- Silica

- Hydrogen Peroxide

- EZ Series Reagents

- EZ Series Accessories

-

Online Sensors and Controllers

Digital Controllers (Transmitters) Controllers (Analogue)

- SC4500

- Orbisphere 366x Ex

- Orbisphere 410/510 Carbon Dioxide

- Orbisphere 410/510 Oxygen

- Orbisphere 410/510 Ozone

- Orbisphere 51x Hydrogen

Multi-Parameter pH & ORP Sensors- 1200-S ORP

- 1200-S pH

- 12mm pH/ORP

- 8362 sc High Purity

- Combination pH/ORP

- Differential pH

- Digital Differential ORP

- Digital Differential pH

- LCP ORP

- LCP pH

Conductivity Sensors- 3400 Analogue Contacting

- 3400 Digital Contacting

- 3700 Analogue Inductive

- 3700 Digital Inductive

- 3798 sc Electrodeless

- 9523 Cation Conductivity

- 9525 DCCP System

-

Automated Lab Systems

Robot Systems

- Multiparameter Online Panels

- Claros Water Intelligence System

- Samplers

- Test Kits & Strips

-

Lab Equipment and Supply

Apparatus

- Brushes

- Clamps, Rings & Stands

- Crucibles

- Crucibles & Casseroles

- Dispensers & Droppers

- Grab Samplers

- Oil and Grease

- Other Apparatus

- Pipet Aids

- Pipettes

- Racks

- Stir Bars

- Tubing

- Weighing Accessories

General Lab Consumables Glassware/PlasticwareInstruments -

Microbiology

Accessories and Chemicals Dehydrated MediaLabware

-

Lab Instruments

- Parameters

-

Software Solutions

-

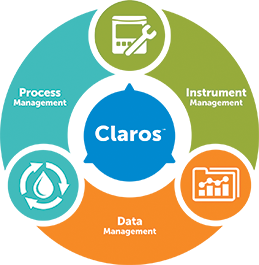

Claros Water Intelligence System

Product Pillars Process Management

- Solutions For:

- BOD/COD Removal

- Nitrification/Denitrification

- Phosphorous Removal

- Sludge Management

Data Management- Solutions For:

- Collection

- Visualization & Analytics

- Reporting

- Data Accuracy

Instrument Management- Solutions For:

- Maintenance

- Troubleshooting

- Remote Access

- Lab and Process Comparison

Industry Challenges Regulatory Compliance Cost Savings Remote Operations Process Optimisation Equipment Maintenance

-

Claros Water Intelligence System

- Industries

- Service

- News & Events

Stainless Steel Digital Contacting Conductivity Sensor, Low Conductivity (k=0.5), Boiler/Condensate Style

- Overview

- Details

- Downloads

- Accessories

- Similar Products

Product #:

D3444B8.99

Unit Price

Contact Us

High performance design

These sensors are manufactured to exacting tolerances using high quality, rugged materials for demanding applications including ultra-pure water, clean-in-place (CIP), and boiler/condensate monitoring. Each sensor is tested to determine its unique, absolute four-digit cell constant. Also, each sensor has a PT1000 RTD temperature element built into its tip for exceptionally fast response to changes in temperature with ±0.1 ºC accuracy.

Resistivity and conductivity measurement capability

These enhanced performance sensors measure from 0.057 µS/cm or 18.2 MΩ (theoretically pure water) up to 200,000 µS/cm.

Versatile mounting styles

Compression Fitting Sensors

Feature titanium electrodes and a compression fitting for universal installation with up to 102 mm insertion depth. The ½-inch or ¾-inch male NPT compression fitting are offered in PVDF or 316 stainless steel. A longer version of this sensor is available for use with a 316 stainless steel ball valve hardware assembly to insert/retract the sensor form the process without stopping the flow. The longer version can also be used for insertion through a compression fitting. Maximum insertion depth is 178 mm.

Non-Metallic General Purpose Sensors

Have graphite electrodes and ¾-inch male NPT threaded PPS bodies. Mount into a standard ¾-inch pipe tee, 1-½-inch Hach union hardware (for cell constant k=10 sensor only), or fasten onto the end of the pipe.

High Pressure and High Temperature Sensors

Are designed for monitoring boiler water and condensate in return lines. They have 316 stainless steel electrodes and threaded bodies (¾-inch male NPT). They can be fastened into a boiler wall using a ¾-inch weldolet or mounted into a process line using a standard ¾-inch stainless pipe tee.

Sanitary Clean-in-Place (CIP) Style Sensors

Have 316 stainless steel electrodes and an integral 1-½-inch or 2-inch flange. These sensors can be installed using standard sanitary mounting hardware.

Full Featured “Plug and Play” with Digital SC Controller

There are no complicated wiring or set up procedures with any Hach SC controller. Just plug in any combination of Hach digital sensors and it's ready to use—it’s “plug and play.”

What's included

Includes: sensor with 6 m cable, digital gateway, extension cable and manual

Specifications

Accuracy:

±2 % of reading above 200 µS/cm

Cable length:

6 m (23 ft.)

Cell constant:

0.5 cm-1

Digital Gateway:

External Digital Gateway

Flow:

0 - 3 m/s maximum, fully immersed

Immersion depth:

72.39 mm

Installation Kit:

3/4" NPT

Installation requirement:

316 Stainless Steel sensor body

Installation style:

Boiler/Condensate

Material (electrode):

Titanium and 316 Stainless Steel

Measuring range:

0.001 - 20 MΩ

0 - 1000 µS/cm

Operating temperature range:

-20 - 200 °C

Pressure range:

0 - 20.7 bar

Repeatability:

±0.5 % of reading

Response time:

90 % of reading within 30 seconds of step change

Sensitivity:

±0.5 % of reading

Sensor cable:

Digital: PUR (polyethylene) 5-conductor, shielded, rated to 150°C (302°F)

Sensor Thread:

0.75"

Sensor type :

Digital

Temperature compensation:

Temperature Compensator: PT1000 RTD

Temperature measurement range:

-20 - 200 °C

Transmission distance:

100 m maximum;

1000 m maximum, when used with a termination box

1000 m maximum, when used with a termination box

Wetted materials:

316 stainless steel and titanium electrodes, PEEK insulator, and fluoroelastomer O-ring seals

What's included?:

Includes: sensor with 6 m cable, digital gateway, extension cable and manual